We have over 10 years of machining experience to produce CNC machined parts manufactured to your specifications. Our dedicated team will work with you throughout the design and production process to get you the parts you need at a cost that works

for you. Huanrui offers the following CNC Machining services:

CNC Turning Service

• CNC Milling Service

• CNC Drilling Service

• CNC Cutting Service

• CNC Grinding Service

• CNC Rapid prototyping

• Wire EDM Machining Services

Plastic : ABS ,PEI,CPVC,PTFE,PMMA, POM ,Acaylic , PEEK, Nylon , Polypropylene Polycarbonate , Polyethylene , PVC ,PET .PSU ,PS,PPSU ,LDPE, HDPE ,etc.

Surface Finishing Options

Surface finish is applied to parts after they have been machined to create a unique surface layer to meet the hardness, chemical resistance, and appearance requirements of the products. It depends on material properties and the application of the part. Heran offers the following finishing options for sheet metal services: Spray painting ,Silk-screening, Transfer-printing ,Electroplating , Laser etching , brush Anodizing ,Bead blasting ,Scouring/ brushing High glaze UV-finish , Embossing ,Polishing Cleaning , Sanding,Chrome-plating, plating , Bake finish ,Anodizing, Texturing, Custom. Fuming PC etc.

Plastic Resin

We can process a variety of plastic materials, including advanced engineering materials with glass fibers (15-50%) like PPA, PPS, PSU, PA6, PA66, PBT, PEEK, LCP, GRIVORY, PET etc.

We are also familiar with PC, ABS, PC/ABS, ASA, PMMA, POM, PP etc.

Mold tests simulating production conditions are performed on every mold.

Using the latest scientific molding process and equipment, Huanrui is capable to analyze every step of the injection molding process to assist in debugging and qualifying the molds.

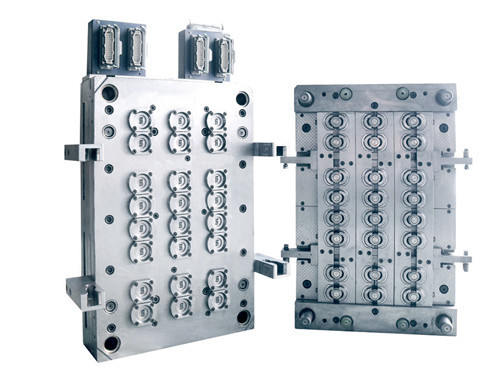

Tooling Technology:

• Multi-Cavity

• 2K Molds

• Insert molding

• Over-molding

• Stack mold

• Unscrewing mold

• Silicon mold